Some of our customers find VALUE in having Precision Coatings, Inc. take care of supplying a COMPLETE COMPONENT. We can machine the basic part, subcontract outside services for complementary surface treatments, provide a thermal spray coating, finish grind the part and sell it as a complete component: This option provides our customers:

- Streamlined Supply Chain Management: 1 P/N, One Supplier.

- Inventory Management

- Ongoing Production Flow

- Eliminates the Hassle of Coordinating 2 or 3 or 4 Operations/Suppliers

- Consolidates All Quality Control With One Entity.

Here is another Case Example of a Complete Custom Part

This Actuator Shaft has coated Bushing Surfaces for enhanced wear resistance at high temperatures. We MACHINE the basic shaft, subcontract ion NITRIDING, HVOF COAT, and finish GRIND this shaft in high volumes to meet a weekly demand schedule.

CLICK HERE for more information on this shaft

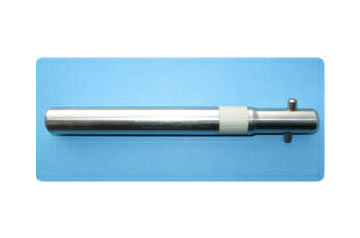

Here is a photo of a Pump Plunger Rod with a Ceramic Seal Area, supplied complete: MACHINED, COATED, GROUND and LAPPED and shipped to meet a JIT Demand Schedule monitored weekly.

Capabilities

We offer full-service support including:

- Design Engineering Assistance

- Prototyping

- Machining

- Subcontracting a Basic Part From a Customer Designated Supplier of Castings, Assemblies, Stampings, or for a Complementary Surface Treatment.

- Thermal Spray Coating (Plasma, Hvof, Arc, Flame)

- Non-stick Coating (PTFE, Fluoropolymers, DURA-SLIDE™ Series)

- Specialty Painting

- Grinding and Lapping

- High Volume Automated Production

- Robotic Application of Thermal Sprayed Coatings.

Precision Coatings, Inc. has a customer focused process to provide quality coatings solutions in many industries including:

- Diesel Engines

- Emission Control

- Wind Energy

- Printing

- Packaging Machinery

- Electronics

- Food Processing

- Pumps

Focus On Performance

At PCI the focus is product performance. The success of each customer’s project is important to us. We offer solutions and work with you every step of the way.

From the initial engineering sessions to the final evaluation of “in- use” performance, you can count on us.

We are Certified to ISO 9001:2015, reflecting our commitment to continuous improvement in our operations. Each day the company strives to engineer and produce coatings that meet industry and customer needs of today and the future.