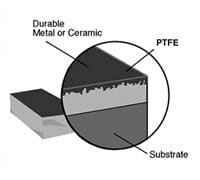

Our most frequently requested and applied non-stick type coating, is our own DURA-SLIDE™. This coating system integrates one of many wear resistant thermal sprayed coatings (i.e. stainless steel, ceramic, tungsten carbide) with a topcoat of PTFE or other similar material. DURA-SLIDE™ is excellent in situations where abrasion, scraping, or other wear is encountered.

DURA-SLIDE™ Durability

A DURA-SLIDE™ Series coating performs better than ordinary coatings because it retains the PTFE or other non-stick material within a hard, wear resistant thermal sprayed metal or ceramic.

These components perform better with DURA-SLIDE™.

- Hoppers

- Rotary Cutters

- Guillotine Blades

- Paddles

- Mixing Bowls

| Ceramics | Metals |

|---|---|

| CeramicsChrome Oxide | MetalsTungsten Carbide |

| CeramicsAluminum Oxide | MetalsStainless Steel |

| CeramicsTitanium Oxide | MetalsChrome Carbide |

What is the DURA-SLIDE™ series?

The DURA-SLIDE™ Series combines a specially applied thermal sprayed metal or ceramic with one of many PTFE-type materials. This combination creates a unique coating system that adds “durability” to the “slide” of PTFE or other similar materials. A DURA-SLIDE™ coating is ideal for use in any situation that requires a durable non-stick (release), dry lube, or corrosion resistant coating.

Thermal Sprayed Coatings include:

- Plasma Coatings

- High Velocity Oxy Fuel Coatings

- Electric Arc Coatings

- Oxy/Fuel (Flame Spray) Coatings